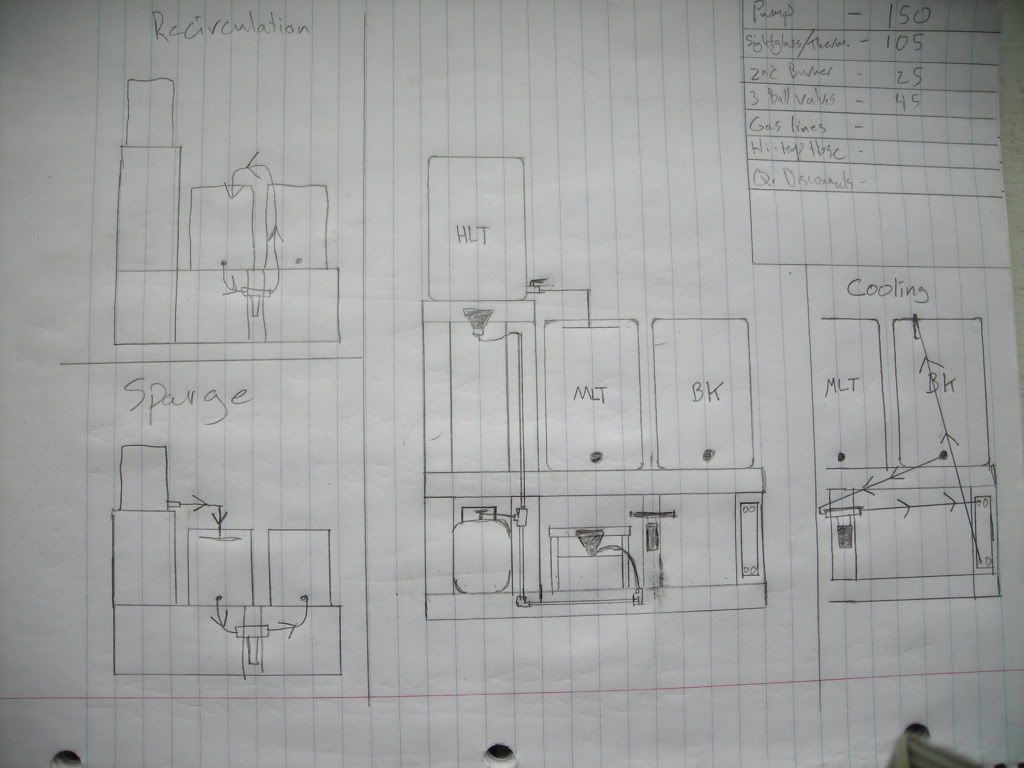

Here is a rough diagram, not to scale, of the two-tier system I am wanting to build. It is a little different than anything that I have come across in that it is a three vessel rig but only has two burners. The HLT would have a dedicated burner while the MLT and BK would share a Banjo Burner which can be moved between the two vessels.

I think the brew day would go as follows:

1. Heat strike water in MLT

2. Dough in

3. Apply heat and recirc. as needed during mash to maintain temp.

4. Heat sparge water in the HLT

5. With around twenty minutes remaining in the mash begin recirculation

6. Once sacc. rest is complete begin fly sparging from the gravity fed HLT and pump to the BK

7. Once the correct volume of wort is collected bring BK to a boil (or possibly begin BK heating while collecting wort)

8. Boil

9. Once the boil is complete begin whirlpooling with pump while simultaneously heat sanitizing the plate chiller

10. Once sufficiently whirlpooled begin cooling with the plate chiller which will recirc. back into the BK to cool the whole batch (pseudo Jamil chiller)

11. Once chilled to pitching temp. run off into fermenters

12. Oxygenate

13. Pitch yeast

14. Drink homebrew

What do you guys think. Any pro's/con's or complete mistakes that you see with this.

Salud,

Beertastic

http://s1233.photobucket.com/albums/ff385/chrissummerhays/?action=view¤t=DSCN3006.jpg