eww wrote:On some sites the banjo is listed as low pressure and it's listed as high on others (the manufacture lists it as high, so I think you're right on this). However, I've read accounts of others using the banjos on low pressure without issue. This is something I need to look into more before making my final decision.

Don't confuse LP (liquid propane) with low pressure. That might be your mistake. No offense taken. You might be able to drill out the jet for a larger volume (at the lower pressure), but you will probably have fuel/air mixture issues.

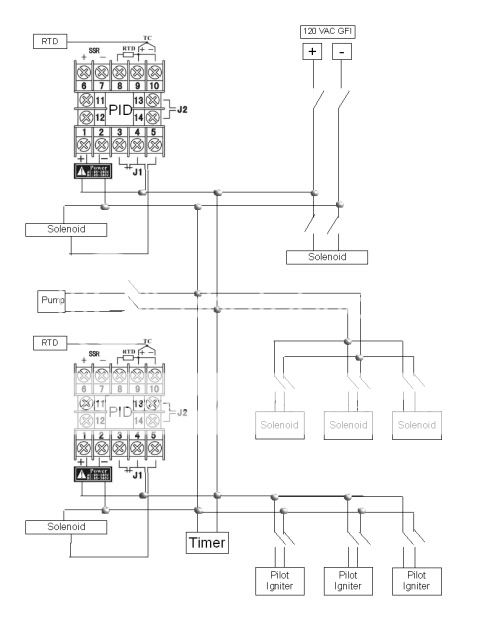

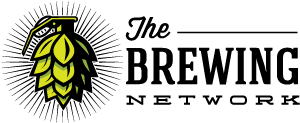

eww wrote:...or 3) a standing pilot that is fired only when needed (so I don't need to get down on the ground to light the pilot after I have the pots in place). In my proposed design it's only the pilots that would be fired by the piezos. The gas for the pilots will be operated on a different switch and solenoid then the gas for the main burner. The main burners will be tied into PID ... not the pilot. I don't see how this is any more unsafe then commercial gas grills, but maybe I'm missing something.

Ok, I see where you are getting at now. I would argue that this is just the standing pilot solution with some built in convenience. I might suggest simplifying slightly and just feed all the pilots off of one solenoid, and have one piezo spark at all three locations. Piezos come it two flavors - mechanical and electrical. I prefer the electrical that continue to spark as long as you hold it down. The mech. ones just spark once for each push.

One thing to keep in mind is that standing pilots are prone to blowing out, and then you risk a eyebrow eliminating boom when the PID turns on your main and the pilot is out (but the burner next to it is on). I'm pretty sure you can put a thermocouples on each pilot to safeguard against that, though - and I would highly recommend that.

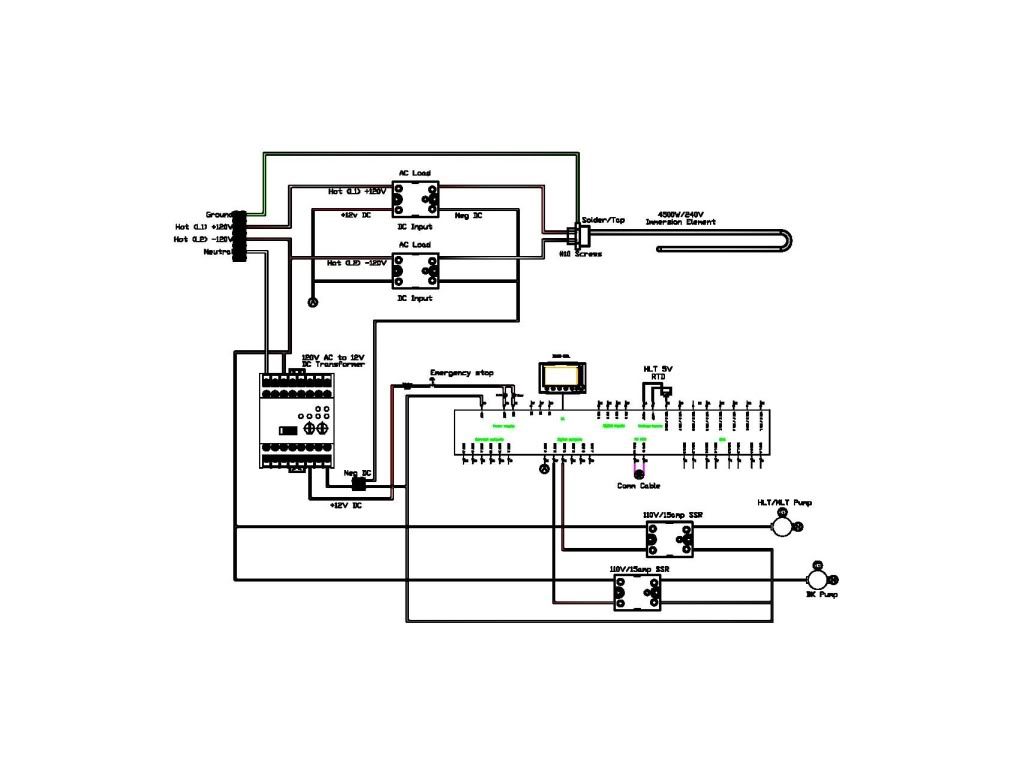

FYI, my answer to this problem was to go with only two burners - one wok burner for the HLT (fired with a Honeywell), and one banjo burner for the boil. I utilize a HERMS coil (which I use later as my chiller) to do step mashing. I am still working on my automation, but I will control the both the HLT burner and the mash pump with PIDs of some kind. The boil kettle does have an ASCO valve and piezo ignitor, but again that's just for convenience.

eww wrote:I'm aware of basic wiring, but this just doesn't make sense to me. No matter how you wire it, the 24 VAC neutral circuit will eventually lead back to the 120 neutral circuit since that is what comes from the source/wall. If it's going through the transformer why should it matter where it re-enters the 120 VAC loop?

The two low voltage leads are a separate circuit. The coils of high voltage induce a current in the secondary coil - but they are for all intents and purposes isolated. You can use a common ground for all DC, not AC.

So now I have enough to understand what you are doing, and I'll take a stab at a diagram.

Mylo