bcmaui wrote:

I'm curious about this.

http://www.arduino.cc/

What do you use to ignite the gas and what type of temp sensors do you use and where do you locate them?

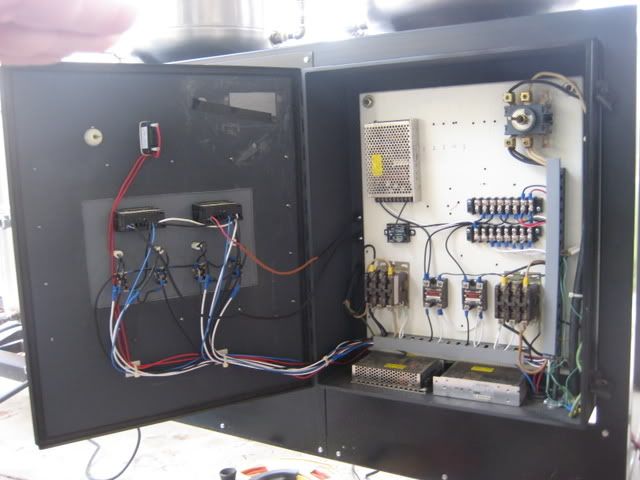

Well... My system is very personalized. I only have two burners (HLT, Boil). I use my Jamil-O-Chiller as my HERMS coil. The only things that I need to control with the Arduino are 1) the HLT Burner, 2) Water Pump, 3) Wort Pump, 4) Hose Solenoid, 5) LED/Buzzer Alarm, and 6) Exhaust Hood (future). The boil kettle burner is a bayou classic and has an ASCO valve for on/off, and a piezo igniter - but those are manual. The HLT burner is a low pressure wok burner and it has a "intermittent pilot retrofit kit" on it (same as on fireplaces). Push button, get flame. The hose, HLT burner and alarm are 24VAC, and 2 pumps (and future hood) are 110VAC. There are 6 relays for all that.

I was originally going to use the PIDS from Auber (and the really slick RTD thermowell probes with quick disconnect). Instead I'll use the Arduino for all the logic, and I will replace the RTD sensors with the Dallas One-Wire chips. The probes get mounted in the MT and HLT, as low as I can get them, so I can do 5G and 10G batches. The thermowells are pricey, but I really like the disconnects.

If you are just getting started, I would recommend looking at the BrewTroller stuff. It's very similar (same Arduino platform). You still get the satisfaction by assembling and configuring your own deal, but they have worked out a lot of the nuts and bolts for you already. In addition to the basics, they enable all this "over the top" valve control automation - but you can choose to implement the things that you want a la carte.

Mylo