Thu Mar 25, 2010 6:58 pm

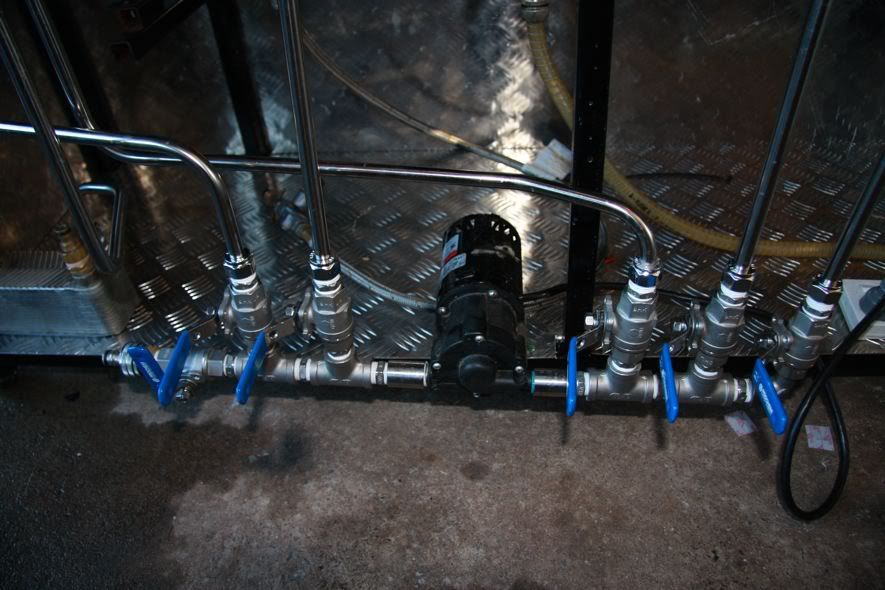

Sorry, should have been more detailed. This is a clip from 5-Star. I use Star-San (across the board final rinse and sanitizer) and Saniclean for CIP. Will try to paste in their description. I run a Saniclean loop at 160F prior to boiling the wort as I need to clean the CFC and tubing for transfer to the conical. Star San for all else, including a large tub for soaking all parts as I go through the brew day, and conical parts as well. 5-Star is a life saver for us homebrewers.

Star San

is an Acid Anionic Sanitizer, accepted by the U.S.D.A as a General Sanitizer in all Departments.

Star San is a synergistic blend providing a unique killing system, unaffected by organic soils and

delivering a self-foaming formulation for optimum coverage and penetration. Formulated to impart no

off-odors or flavors, Star San is a No-Rinse sanitizer when used at 200 ppm. Unlike other sanitizers,

Star San is non-staining on your equipment and hands, non-corrosive on stainless, and stable over a

wide temperature range.

Saniclean

is an Acid Anionic Final Rinse. Saniclean is formulated to be low-foaming at temperatures over 70" f

and is also unaffected by organic soils. Formulated to impart no off-odors or flavors, Saniclean is a

No-Rinse product when used as directed. Saniclean is also non-staining on your equipment and hands,

non-corrosive on stainless, and stable over a wide temperature range. When allowed to air-dry,

Saniclean leaves your brewing equipment in an acid condition, inhibiting contamination between uses.

Conical Fermenter - Amber Lager

Keg#1 Dunkel

Keg#2 Helles

Keg#3 Flanders Red

Keg#4 Star San

Keg#5 Star San

Keg#6 Star San